Services

Uncompromised Automotive Craftsmanship and Artistry

“Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction, and skillful execution.”

– William A. Foster

Your Premier Destination for Classic Car Excellence

At Kiddy’s Classics, we’re passionate about classic automobiles. Our commitment to excellence shines through every service we offer. Whether you’re a devoted classic car enthusiast or just beginning to appreciate the timeless beauty of these vehicles, our team is here to guide you through a world of unparalleled craftsmanship and care.

Our Services

Explore our services and discover why Kiddy’s Classics is the top choice for classic car enthusiasts.

Description of Services

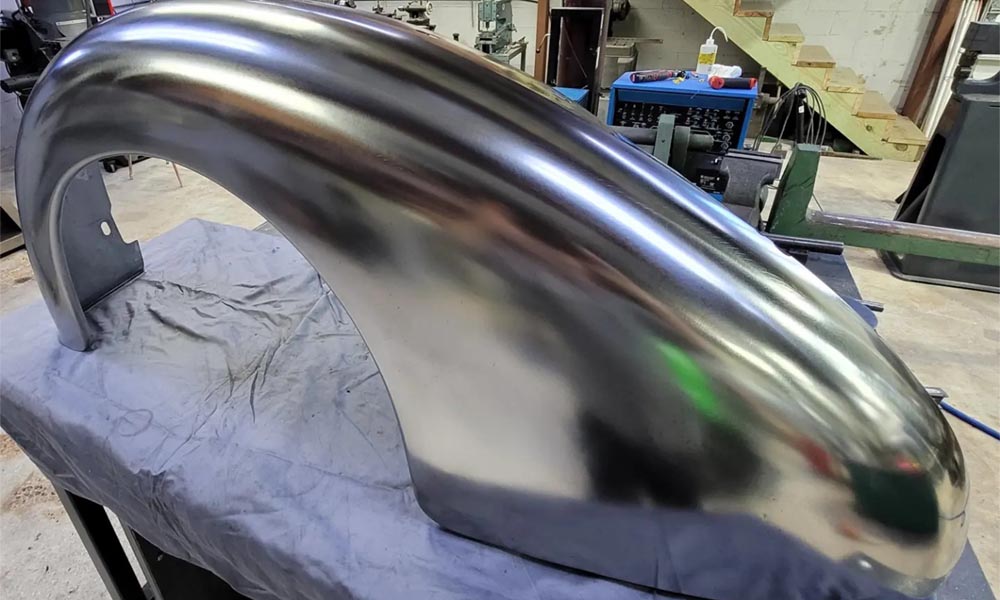

Metal Fabrication and Rust Repair

The foundation of a vehicle is often the most overlooked. Less-than-desirable repairs are easily hidden under layers of body filler and primer. With over 20 years of experience stripping vehicles for restoration, we know what types of repairs last and why other methods of repair fail. Our approach is simple, we don’t just fix the problem, we fix the source of the problem. When we complete a repair, it will look as though we were never there; the weld seam will be smooth, the contours of the original panel will be accurately measured and reproduced, and the size and depth of the spot welds will be replicated so that even the most discerning of eyes will not be able to detect where the repair was made.

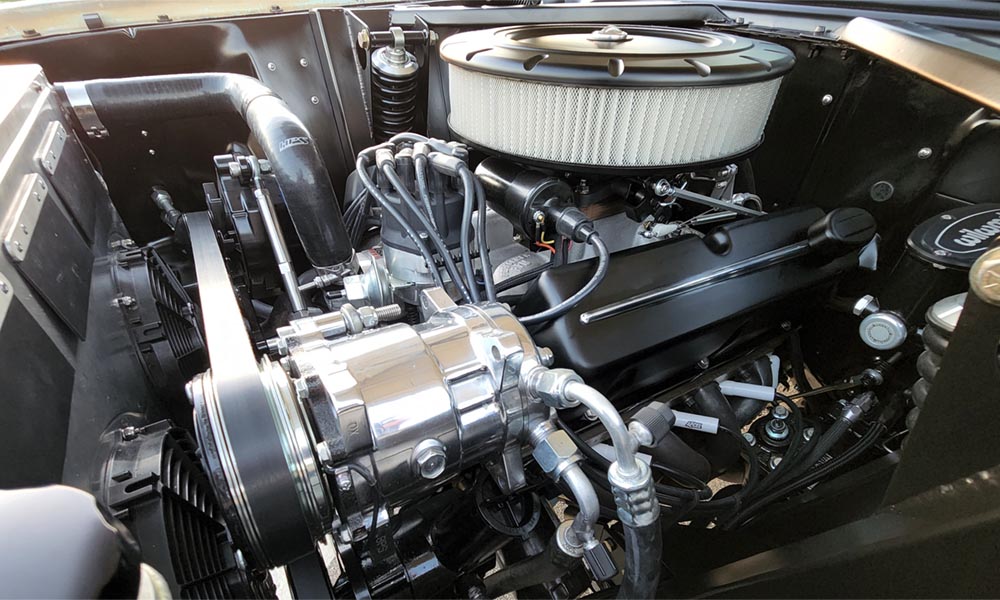

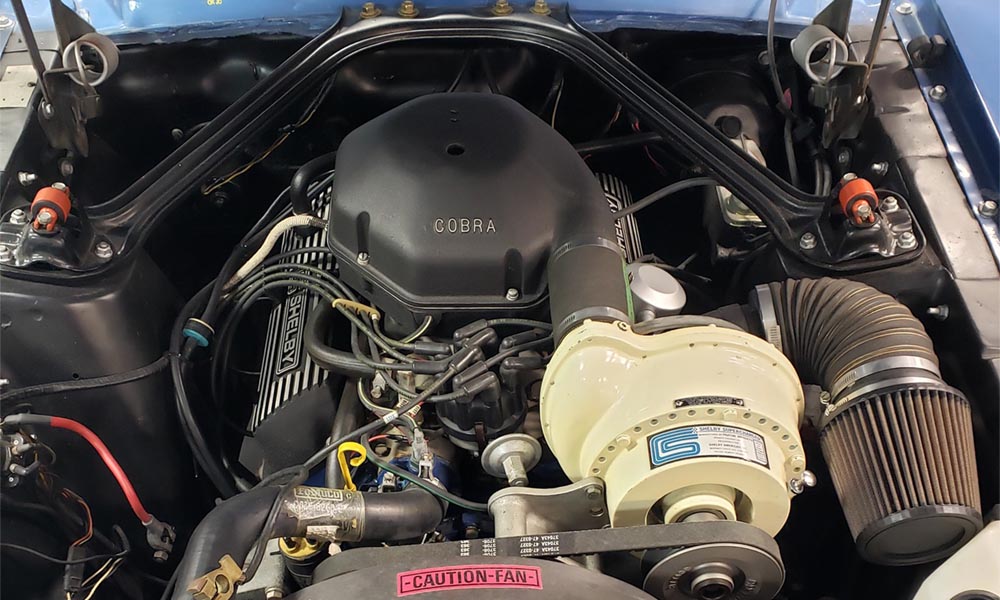

Fuel system calibrating and conversions

Whether it is carburetion or fuel injection, we have the tooling to properly measure your system’s current performance and the knowledge to precisely determine what needs attention. We take a comprehensive system approach to ensure all components are engineered to work together. If you’re looking to make a change toward a fuel injection system, we are fully capable of the correct installation and setup from beginning to end. The overall efficiency of your engine depends heavily on the ability of the air-fuel mixture to be properly balanced. Just like a vacuum gauge and gas analyzer are necessary tools to accurately measure a carbureted engine’s performance, so are a laptop and software when it comes to fuel injection. We’ve got you covered for all fuel systems requiring service.

A/C Installation and Service

Whether it is carburetion or fuel injection, we have the tooling to properly measure your system’s current performance and the knowledge to precisely determine what needs attention. We take a comprehensive system approach to ensure all components are engineered to work together. If you’re looking to make a change toward a fuel injection system, we are fully capable of the correct installation and setup from beginning to end. The overall efficiency of your engine depends heavily on the ability of the air-fuel mixture to be properly balanced. Just like a vacuum gauge and gas analyzer are necessary tools to accurately measure a carbureted engine’s performance, so are a laptop and software when it comes to fuel injection. We’ve got you covered for all fuel systems requiring service.

Performance Enhancements

Modern technology can greatly improve the performance and handling of almost any classic vehicle. Improvements to the suspension, braking, fuel management, and even lighting can give your vehicle a more comfortable and overall safer feel. In addition, the horsepower and torque that is available in today’s modern engines were once thought almost impossible in a daily driver application. With so many options and upgrades available, the most important thing to remember is to strive for balance when it comes to performance upgrades. In short, you determine how you want your vehicle to ride, handle, and perform and we will make it happen. If the part you need doesn’t exist, no problem! Our fully equipped fabrication department can design and fabricate anything necessary to make your vision a reality. Give us a call today and let us know how we can tailor your ride to meet your needs.

Metal Finishing

We believe that a vehicle should be crafted, not sculpted out of body filler. A true automotive enthusiast knows it is what you can’t see under the paint that truly determines the quality of that vehicle. At Kiddy’s, great care is taken to accurately remove the distortion in a panel just as it was performed prior to the introduction of plastic body fillers and high-build primers. In doing so, the end repair has little to no need for additional bodywork. This method provides for the best foundation by needing the least amount of material build-up prior to paint.

Media Blasting

The number one cause of failure we see in a paint finish is caused by a lack of adhesion due to poor surface preparation. If you desire a finish that will remain beautiful for years to come, we advise establishing the best foundation through media blasting the surface and top coating with Glasurit epoxy. This combination provides a superior bond, ensuring a durable final finish. Here at Kiddy’s, we have a dedicated blasting booth large enough to fit the entire shell of a vehicle so that every square inch of your vehicle can be efficiently prepped for top coating. When a vehicle is restored with us, we separate the inner and outer structure of all panels at the spot welds, to expose the rust you are not able to see, which often hide inside the seams. Once the panels are separated, we fully media blast all exposed rust, prior to reassembling the panels. While this process does add time to the total build, it is the only way to ensure a lasting finish.

Bodywork and Paint

Shiny paint jobs are sought by all, others looking to turn heads want the final finish to be smooth and flat. However, if you are one of the few looking for a finish that raises goosebumps every time you see it, the vehicle needs to be accurately contoured. This process requires not only an accurate foundation but also the use of panel sweeps. Our panel sweeps are similar to those used during the vehicle’s initial design stage as a clay sculpture and are intended to replicate, and sometimes accentuate the original contours of the body. At this level, the body of the vehicle embodies what the original designers intended it to envision. The highlight lines on the vehicle should flow consistently from front to back, and twist smoothly through any reverse curves. Only the discerning few can appreciate a car at this level.

We continuously push to achieve a higher level of finish with every build we do. We strive to ensure our vehicles are crafted in a manner that we are proud to stand behind for years to come. To achieve this, a meticulous amount of time must be spent at each phase of the build process, refining that last ten percent; this assures the final finish can be accomplished with the absolute least amount of material because any more than that would take away from what the vehicle was intended to be.

Fiberglass Repair

While fiberglass panels are much easier to form and/or repair compared to steel or aluminum, original fiberglass is prone to cracking. To avoid these cracks from forming special care is given to inspect and reinforce any areas of concern. Additionally, while fiberglass itself will not rust the steel structures that fiberglass is commonly riveted over does. The steel structure on a fiberglass vehicle is what provides structural integrity. If rust is found while performing a fiberglass repair, we take every step needed to eliminate the rust, repair any damage to the steel structure and then coat all metal components in epoxy to prevent the rust from returning. The epoxy coating will also improve the adhesive bond between the fiberglass and steel.